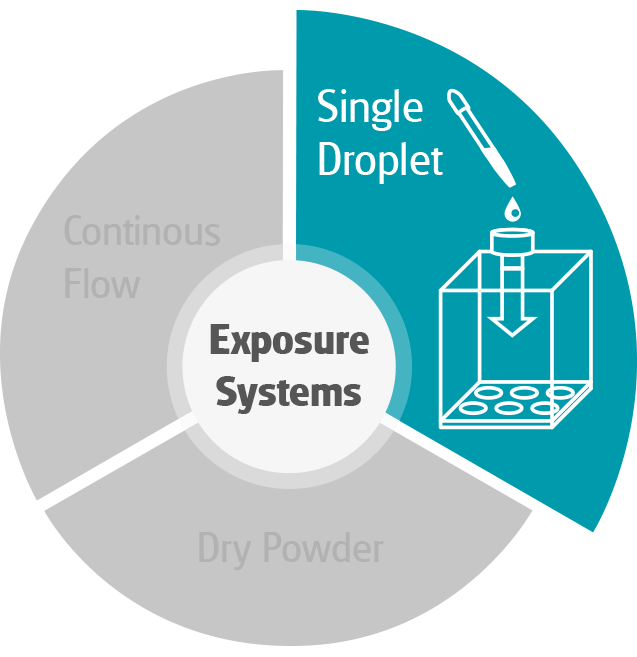

Single Droplet Sedimentation Systems are specifically designed for dose-controlled and spatially uniform deposition of liquid aerosols on cells. Test substances are chemicals or particles brought into suspension with e.g. PBS.

The aerosol is applied for a short time of approx. 7 – 10 minutes.

This method is well suited for scarce and expensive materials, such as new drug candidates or particle samples from the environment.

Nebulization volumes range from 15 – 300 µl (Cloud Alpha Move 500 µl). Aerosolization is performed directy into the cell culture exposure chamber. Aerosolization can be repeated several times to obtain a dose-response profile.