Modules for 6-well sized inserts

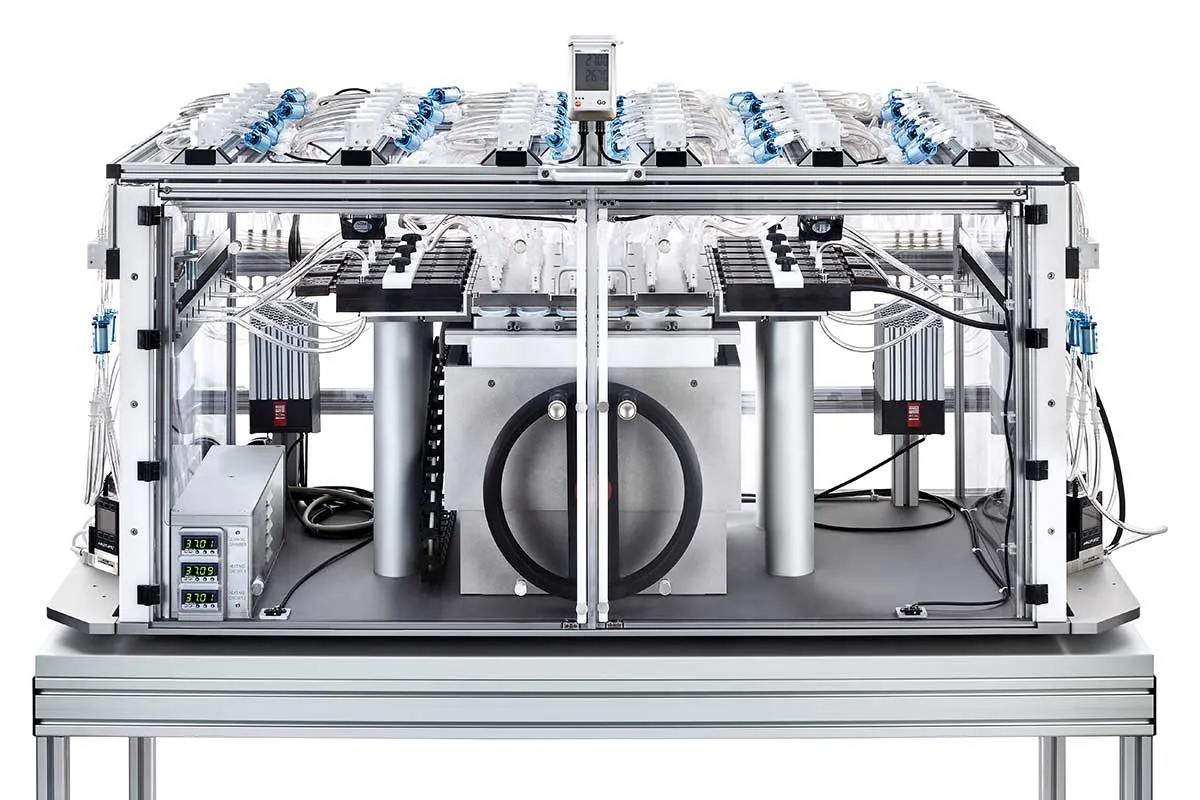

The VITROCELL® 6/48 module system has been specifically designed and engineered to facilitate the research of mammalian cell cultures in direct exposure to airborne substances such as gases, complex mixtures, nanoparticles and fibers. The system authentically simulates the conditions of human physiological exposure.

Only one system is required: 7 dilutions with 6 inserts are used for exposure to the substances and 6 inserts in the same system for clean air control. The cells are exposed at the air / liquid interface on 48 cell culture inserts using low flow rates of the aerosol. A complete dose / response profile can be obtained in one experiment. After exposure, the cells are further processed to measure a wide range of endpoints, e. g. cytotoxicity, genotoxicity, proliferation, cellular and oxidative stress as well as inflammation (see also VITROCELL® assay guide).

The base module has been designed for 48 cell culture inserts. The media is supplied individually to each well compartment.

Temperature is electronically controlled at 37° C (99° F) by means of a heated base plate. Therefore, an additional incubator is not required while using this module. The base module is made of aluminum with media compartments of stainless steel. It is autoclavable at 121° C (250° F) for 20 min. This module is renowned in scientific circles for its reliability and durability.

The docking station with special sealing and connection mechanisms guarantee a hermetic connection of the base module with the aerosol exposure top.

The aerosol inlet-stream flows through specifically shaped inlets. They are available in stainless steel or stainless steel with unique VITROGLIDE surface treatment for lowest adhesion results. The stainless steel / VITROGLIDE inlets are specifically designed for aerosols containing nanoparticles.

The aerosol inlets are connected to the distribution or dilution systems. Extraction from the module takes place via small holes using a controlled vacuum flow. VITROCELL® calibration valves, which are connected to a vacuum pump, control flow rates effectively. The aerosol exposure top features an in/outlet for heating the water circuit, ensuring corresponding temperatures with the base module. It is made of high-quality anodized aluminum and titanium.

The module has been designed for 48 cell culture inserts (6-well size).

Available adaptor set for:

Heating Systems for base module and climatic chamber to avoid effects of aerosol condensation.

VITROCELL® exposure systems have been specifically designed and engineered to give researchers the possibility of directly exposing mammalian cells or tissue at the air/liquid interface. Thus, all cell types cultivated on microporous membranes can be used. This approach allows for more credible and authentic results than by submerged exposure due to a closer replication of the human physiology.

We are here to help.

Don't hesitate to contact us on your questions regarding our products and services!