Compact Horizontal Flow Exposure Module

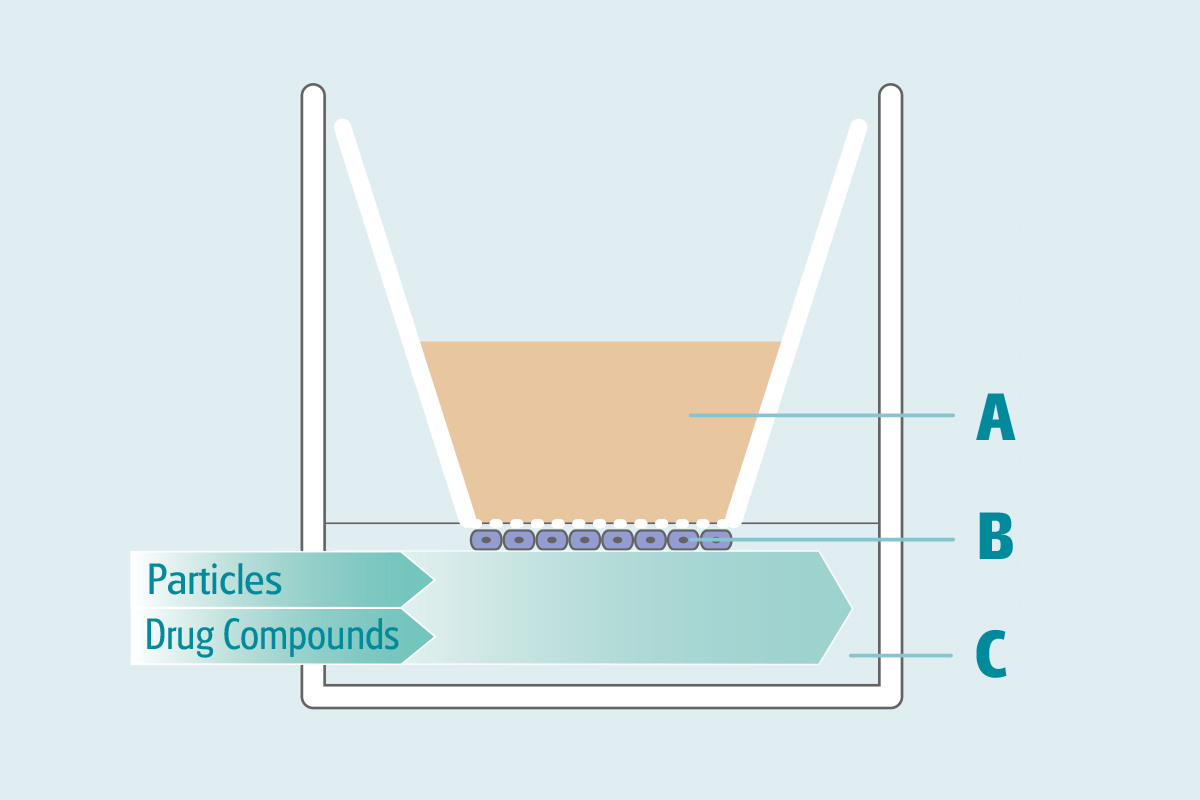

The unique feature of Navetta is its active deposition mechanism while exposing cell cultures in horizontal flow on inverted inserts. Instead of relying on gravity or diffusion, Navetta applies an electric field to actively direct charged aerosol particles onto the cells grown at the air–liquid interface (ALI).

This leads to significantly higher deposition efficiency, even for very small particles (< 100 nm) that are otherwise difficult to deposit.

Navetta is an ideal tool to exposure cell cultures to particles and drug compounds in combination with the VITROCELL® PowderX or Preciseinhale® aerosol generators. Due to the integrated humidification system, longer exposure durations are possible.

The combination of laminar airflow and electrostatic attraction ensures uniform particle distribution across all exposed cell culture inserts.

All VITROCELL® exposure devices have been specifically designed to enable direct exposure of mammalian cells or tissue at the Air/Liquid Interface in physiologically relevant conditions. Here the cell cultures are not covered with media as opposed to submerged conditions which cause an undesired interaction of the formerly airborne substances with the culture media. This approach allows for more credible and authentic results than by submerged exposure due to a closer replication of the human physiology.

A: Media in inserts

B: Cells on membrane

C: Direct and controlled exposure of test atmosphere to cells

The system ensures that the airflow remains laminar and gentle, so the electric field enhances deposition without damaging the cell cultures. In general, particles in an aerosol carry some electric charge naturally (due to friction, atomization, or handling). Navetta allows for controlled charging of the aerosol particles via corona charging before and applying high voltage during their passage through the chamber. Control experiments demonstrated that this process has no influence on cell viability. The corona charger applies a high voltage to ionize the air and transfer charges to the particles, giving them a known polarity (positive or negative).

Testing of pharmaceutical compounds delivered by commercially available inhalers (DPI/MDI) is best performed with the Preciseinhale®. The aerosol is guided with controlled flow directly to the Navetta exposure module. If small quantities of loose powder or pharmaceutical compounds need to be tested, the VITROCELL® PowderX is coupled to the Navetta.

The exposure chamber maintains 37 °C and 95% relative humidity, mimicking the conditions of the human airway while maintaining cell cultures viable and functional over extended exposure periods. This makes it suitable for sensitive epithelial or co-culture systems that require gentle, yet precise, aerosol delivery.

Inside the Navetta exposure chamber, an uniform electric field across the exposure area is generated between upper electrodes and a grounded plate. The strength of the field can be tuned at each insert postion to the desired deposition rate. Charged particles experience an electrostatic force within this field and are actively driven to the cell surface, resulting in high, uniform deposition efficiency.

Normally, cells are seeded on the upper (apical) side of a porous membrane in a cell culture insert (e.g. cellQART®, etc.) and grow while the insert sits upright. In inverted cultivation the insert is positioned upside down and cells are seeded onto the lower (basal) surface of the membrane which is then facing up. After attachment, the insert is brought back to its normal orientation to continue the culturing and then to carry out the exposure in the Navetta. A detailed protocol is part of the delivery.

We are here to help.

Don't hesitate to contact us on your questions regarding our products and services!