The Organ-on-Chip Exposure Solution for Gases and Complex Mixtures

In the VITROCELL® Continuous Flow AX12 the advanced in vitro model is exposed to a continuous flow of gases, complex mixtures or particles. Only this exposure principle is suitable for aerosols in which both gas and particle phase are of relevance. Continuous Flow Exposure is used for gases, chemicals or materials which are available in larger quantities (several g) under a constant delivery. When scarce and very expensive materials need to be tested, this method is less suitable. We recommend in these cases Single Droplet Sedimentation in the Cloud Apha AX12 or Dry Powder Exposure in the Powder AX12 Systems.

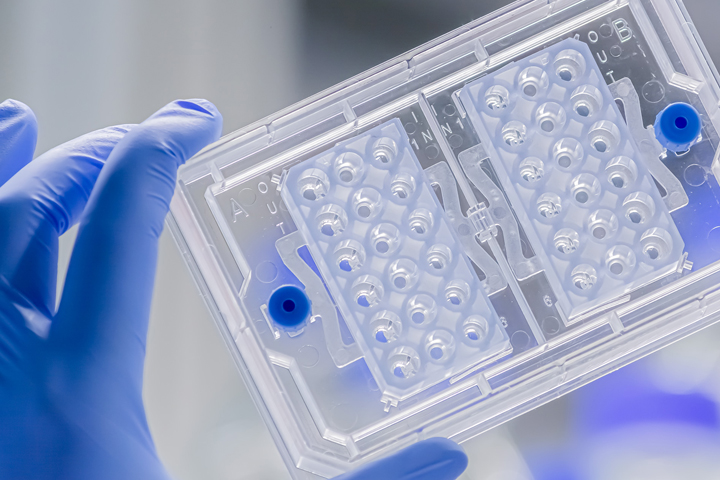

The AXLung-on-Chip System allows in vitro modeling in outmost physiological conditions by replicating the essential key features of the lung microenvironment.

The combination of the breathing-induced cyclic stretch and the optimized ultrathin cell culture substrate (AX membrane) preserves lung cells’ functionality and phenotype. The technology provides answers to fundamental questions about lung biomechanics and cell biology. Furthermore, it is a powerful tool to recreate healthy, diseased, and personalized in vitro models, which can be implemented in drug development to test molecule efficacy and safety, and in toxicity assessment of e. g. pollutants, chemicals and consumer goods. This will hopefully lead to more animal free product development in the future.

Aside the AX12, the system is made up of three further components: two pneumatic controllers, AX Breather and AX Exchanger, and the AX Dock which is the interface between these two devices and the AX12.

A nature-inspired concept is used to recreate the breathing motion. The ultrathin AXmembrane (blue) is deflected by applying negative pressure inside the basal chip chamber through an integrated micro-diaphragm (grey).

We are here to help.

Don't hesitate to contact us on your questions regarding our products and services!