Highest automation and reproducibility

The VITROCELL® AirTox Monitor is designed for automated exposure of lung cell cultures at the Air/Liquid Interface with full control of all relevant parameters such as temperature, humidity, exposure duration and flows.

Special focus was set to minimize the needed lab space and increase reproducibility in a lab environment with frequently changing staff.

The VITROCELL® AirTox Monitor ensures this reproducibility by a user-friendly control software. All relevant process steps of the cell exposure are automatically prepared and relevant parameters such as temperature, humidity and flow rates are exactly controlled to target values of the recipes.

A high degree of automation and user guidance ensures reproduceable conditions day-by-day independent of the operator or location.

For increased flexibility in the experimental setup, the system can be connected to a wide range of aerosol sources. The new adaptable PM inlet offers defined ranges of particle sizes to the exposure module. Flow rates can be adjusted according to the sensitivity of the cell culture system.

The control software is operated via an industrial tablet PC and provides an intuitive operation of the system. The system carries out all process steps automatically and supports the operator with step-by-step instruction for all steps from preparation to experiment and post processing.

For high repeatability, the aerosol is sampled isokinetically from the main flow. This is the method of choice for reproducible and representative sampling according to guideline VDI 2066 and standard literature. With the new adaptable isokinetic sampling unit, a set of flow parings is now available.

| Main flow (l/min) | Sample flow (ml/min) | ||

|---|---|---|---|

| – | 100 | 50 | 25 |

| 16.67 |  |

|

|

| 8.33 | – |  |

|

The VITROCELL® adaptable PM inlet separates different fractions of the aerosol before the aerosol is guided into the AirTox Monitor. Depending on the desired particle size and the amount of aerosol available, the PM inlet can be equipped with different nozzle plates.

| PM | Flow rates l/min (m3/h) | ||

|---|---|---|---|

| – | 16.67 (1) | 8.33 (0.5) | 6 (0.36) |

| 10 |  |

|

|

| 2.5 |  |

|

|

The VITROCELL 6/1 module is specially made to integrate a variety of dosimetry technologies available at VITROCELL for example:

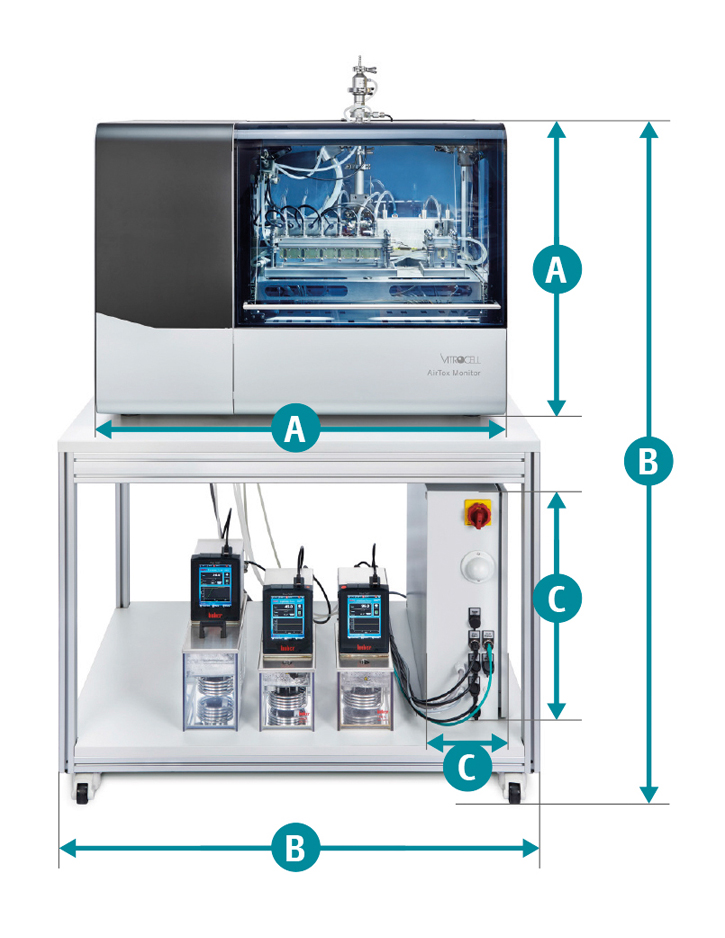

| Dimensions: | Weight: | |

|---|---|---|

|

760 x 1056 x 600* | 150 kg |

|

1720 x 1200 x 750* | 300 kg |

|

600 x 600 x 250* | 32 kg |

*(height x width x depth in mm)

We are here to help.

Don't hesitate to contact us on your questions regarding our products and services!