The high end smoking robot for conventional and electronic cigarettes.

Cutting edge technologies make the VITROCELL® smoking machine VC 10® S-TYPE a perfect tool for evaluation of conventional and e-cigarettes.

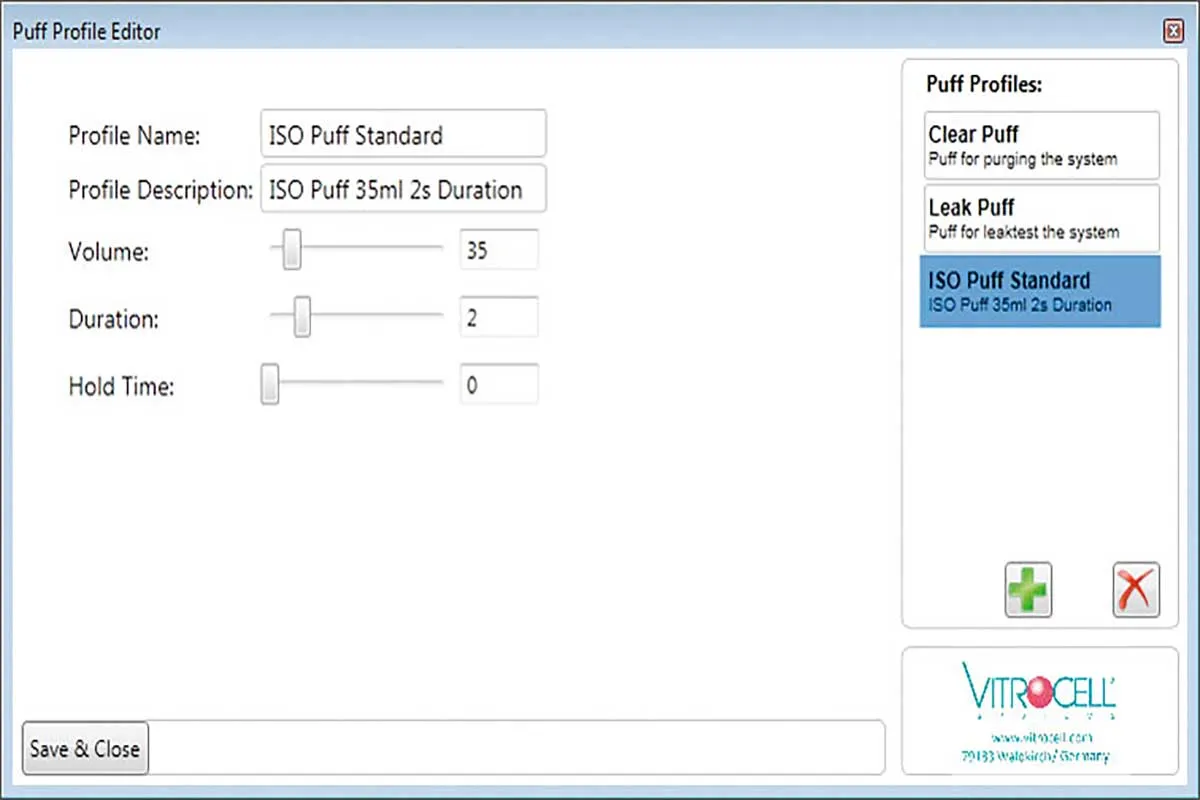

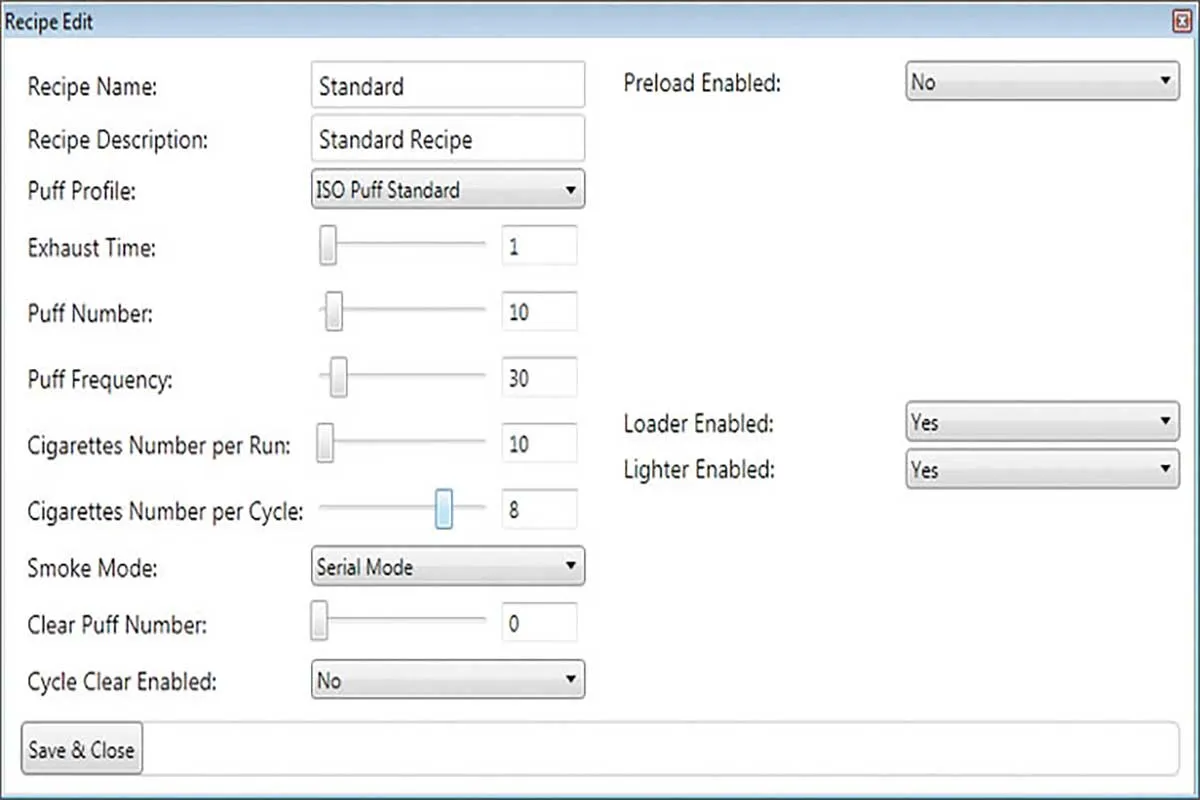

This smoking machine features all special requirements for high-class research: compliance with ISO, Health Canada and square puff profile protocols as well as ease of handling, fast cleaning and high speed product change capabilities.

It is suitable for working with side- and mainstream smoke, and offers significant advantages over other smoking machines.

Now continuous smoking and selective guidance of the aerosol to max. 6 exhaust lines are possible.

Up to 10 devices can be installed on the support rim with individual button actuators.

The system is available for all commercial HTP devices.

Button activated e-cigarettes put the user of smoking machines into a problem: should one press the button every 30 or 60 seconds manually? The automated solution to press the button in a precise manner is the VITROCELL® Vapestarter. The device can be connected to any VITROCELL® smoking machine. The trigger function is controlled by the software of the smoke generator. The system consists of Vapestart Controller, e-cigarette holder and different Vapestarter units. The Vapestarter units are tailor-made to fit tank products having different diameters as well as square shapes.

The magazine stores up to 300 cigarettes and has a machine-controlled feeding and aligning system.

There is the option to activate the leak detector prior to each experiment. The detector confirms the tightness of the system including cigarette holders and pump. The results are logged in the study files.

The rotation of the port holder is controlled by a stepper motor with highest precision.

The Cambridge filter can be mounted easily into the system for analytical purposes.

The integrated fan evacuates the sidestream smoke. The air flow at the cigarette holders is adjusted by the fan speed.

The IR-sensor can be adjusted to a fraction of a millimeter and transmits reliable signals to the pump and butt extractor. If the critical butt length is reached, the pump stops immediately. Alternatively, it is also possible to work with a defined number of puffs.

The cigarette butts are removed from the holder by ejection. The ashtray is kept permanently clean with a brush.

The syringe pump is controlled with high precision by a strong linear motor. Due to the special design, the syringe can be dismantled for cleaning and refitted again in a very short time.

The machine can be scaled up to 3 syringe drives to increase the puff frequency.

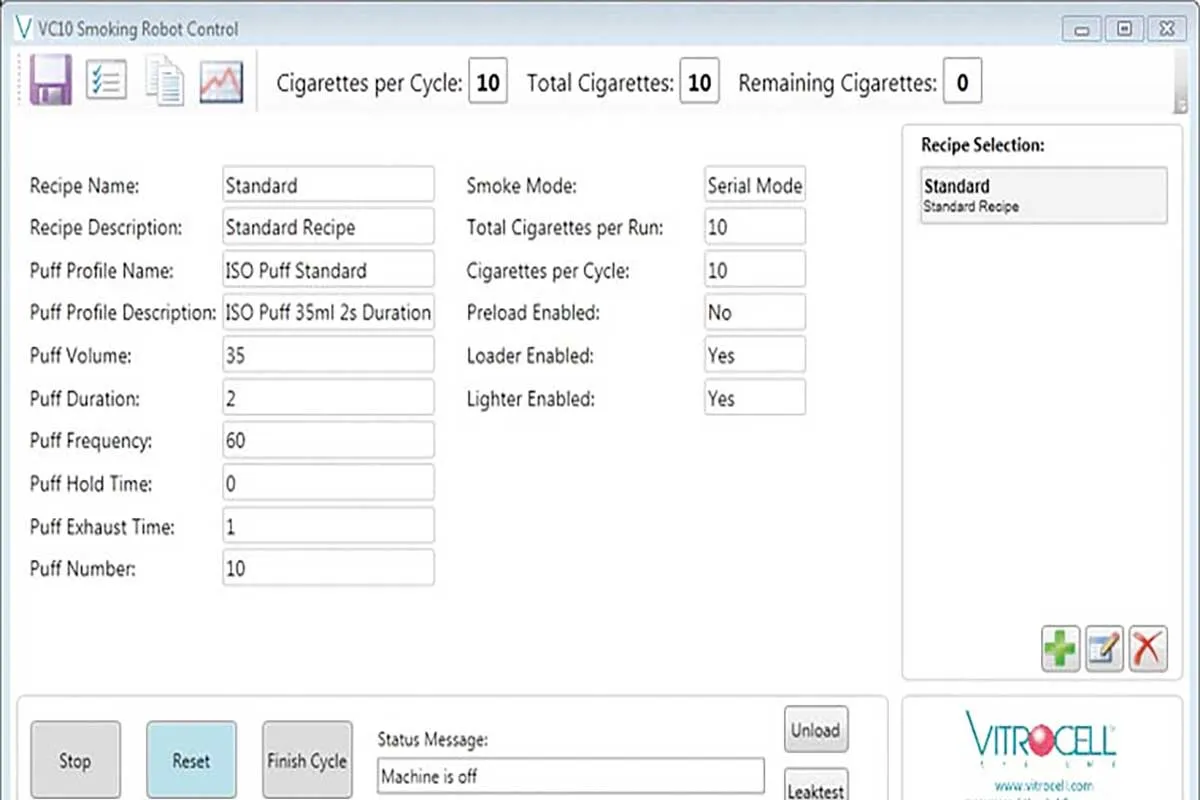

The control box houses the controls for the stepper motors, sensors and pneumatic valves. The whole process is controlled by Beckhoff software in conjunction with Microsoft Windows 10®. This setup offers extensive possibilities for integration with common Microsoft Office® applications and the exchange of data with Excel®-sheets.

We are here to help.

Don't hesitate to contact us on your questions regarding our products and services!